From a napkin sketch to manufactured product, Concinity can help with each step of the product development cycle.

Hard engineering: Mechanism dynamics and Finite Element Analysis. Calculations, thermal modeling, tolerance analysis, and geartrain design.

Concinity knows how to get your parts made, and where to get them. Rapid prototype sources for SLA, SLS, short-run injection molds, investment castings, sheet metal, and more.

Concinity can lead cross-functional teams to keep your development project on time, on budget, and on target.

Working with your manufacturers across the world or in the US with collaboration tools and solid experience.

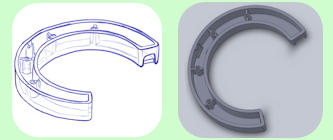

Concinity can provide concept generation and brainstorming, CAD modeling including complex surfacing, tooling-ready data for injection molded and cast parts, and production drawings and documentation.

Concinity seeks creative and clean solutions to the toughest design problems; "brute force" is rarely the best path.

Results of this thinking can be reduced parts count and part cost, additional intellectual property, and a design that is true to the soul of the product — embodying aesthetics, simplicity, function, and cost effectiveness.